Insulyte 11

Insulyte 11 Trade Information

- Minimum Order Quantity

- 100 Bags

- Supply Ability

- 1000 Bags Per Day

- Delivery Time

- 1-7 Days

About Insulyte 11

Insulating castables are refractory materials have low bulk density, lower thermal conductivity & high porosity, They are designed to provide thermal insulation in high-temperature applications. These materials are typically composed of lightweight aggregates and a binder. Insulating castables are commonly used in back up lining.

- Product:Insulyte 11

- =====================

- Product Class: Refractory Monolithic

- Type:Medium Density Insulating Castable

- Nature of Bond:Hydraulic

- Installation:Tamping

General Properties

- Max. Service Temperature: 1300 c

- Maximum Grain Size: 6 Mm

- Water Required for Casting: 29 - 34 %

CHEMICAL ANALYSIS, %

|

|

RANGE |

TYPICAL VALUE |

TEST PROCEDURE |

|

Fe2O3 |

3.00 - 3.50 |

3.35 |

BIS 12107 Part 6 |

PHYSICAL PROPERTIES

|

|

RANGE |

TYPICAL VALUE |

TEST PROCEDURE |

|

Dry density, g / cc after drying at 110 C / 24 hrs |

1.20 - 1.35 |

1.28 |

BIS 10570 |

|

CCS, kg/cm2 after drying at 110 C / 24 hrs after heating at 1100 C / 3 hrs after heating at 1300 C / 3 hrs |

35-50 25-40 40-55 |

40 30 50 |

BIS 10570 BIS 10570 BIS 10570 |

|

% Retained on maximum size |

0-5 |

1.4 |

BIS 1528 Part 14 |

THERMAL PROPERTIES

|

|

RANGE |

TYPICAL VALUE |

TEST PROCEDURE |

|

Refractoriness, Orton / C |

|

14 / 1398 |

BIS 1528 Part 1 |

|

PLC, % |

|

|

|

|

after heating at 1100 C / 3 hrs |

(- 0.30) to (+0.30) |

-0.19 |

BIS 10570 |

|

after heating at 1300 C / 3 hrs |

(+ 0.20) to (+1.00) |

+0.80 |

BIS 10570 |

|

Thermal Conductivity, |

|

|

WATER |

|

kcal/m/hr/C |

0.30 - 0.35 |

0.325 |

CALORIMETRIC |

|

at 500 C HF |

|

|

METHOD |

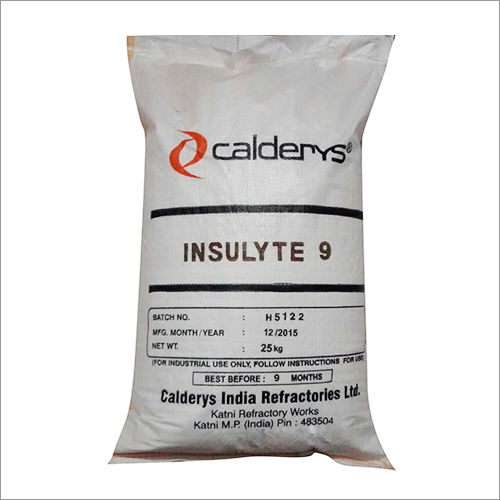

- Packaging: 25 kg bags

- Delivery State: Dry

- Storage Life: Best till 9 months from the date of production, if stored in proper condition.

Note:

The data are current production averages. They can not be used as limits for specification.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Insulating Castables Category

|

S.K GUPTA PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry