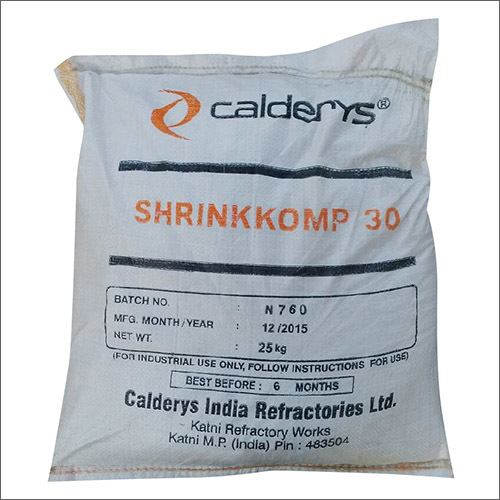

Calderys Shrinkkomp - 20, 30, 40

Calderys Shrinkkomp - 20, 30, 40 Specification

- Compressive Strength

- 60 MPa (at 28 days) Megapascals (MPa )

- SO3 %

- 3%

- Color

- Grey

- Weight

- 50 kg Kilograms (kg)

- Initial Setting Time

- Approx. 3045 minutes Minutes

- Bending Strength

- 8 MPa (at 28 days)

- MgO %

- 5%

Calderys Shrinkkomp - 20, 30, 40 Trade Information

- Minimum Order Quantity

- 10 Bags

- Supply Ability

- 1000 Bags Per Day

- Delivery Time

- 1 Week

About Calderys Shrinkkomp - 20, 30, 40

SHRINKKOMP GROUTING CEMENT

This cement is specifically designed to address the issue of concrete shrinkage. It is a ready-to-use cementitious material that is non-metallic, free-flowing, and non-rusting. One of the key features of SHRINKKOMP grouting cement is its permanent expansion. Unlike other materials that use gas-forming agents for temporary expansion, this cement provides controlled expansion for a permanent bond between machines and foundations. Additionally, it does not contain chemical accelerators like chloride for early strength development. SHRINKKOMP grouting cement possesses high compressive strength and is self-leveling, making it suitable for both static and dynamic loads. It is commonly used for anchoring bolts, machine base plates, bridge bearings, and strengthening machine bases and column foundations.

TYPE:

1. Shrinkkomp 30

2. Shrinkkomp 20

3. Shrinkkomp 40

FAQs of Calderys Shrinkkomp 20, 30, 40:-

Q1. What is Calderys Shrinkkomp?

A: Calderys Shrinkkomp is a specially formulated non-shrink, high-strength cementitious grout available in grades 20, 30, and 40. It is used for precision grouting applications in construction and industrial projects.

Q2. What is the difference between Shrinkkomp 20, 30, and 40?

A: The numbers (20, 30, 40) represent the compressive strength grades of the grout in MPa. Higher grades like Shrinkkomp 40 are used for heavy-duty and high-load-bearing applications, while Shrinkkomp 20 and 30 are suited for medium to general grouting needs.

Q3. Where is Calderys Shrinkkomp commonly used?

A: Calderys Shrinkkomp is widely used for grouting machine foundations, base plates, columns, precast structures, anchor bolts, bridges, and other civil engineering applications requiring strong, non-shrink support.

Q4. What are the benefits of using Calderys Shrinkkomp?

A: The product offers excellent compressive strength, non-shrink properties, durability, resistance to cracking, and easy application, ensuring long-lasting stability in structural foundations.

Q5. How is Calderys Shrinkkomp applied?

A: Shrinkkomp is mixed with clean water to form a smooth grout and poured or pumped into the required area. The surface should be properly prepared, clean, and moist before application for best results.

Reliable Strength and Consistency

Calderys Shrinkkomp grouts deliver consistent performance with high early and final strengths. Suitable for critical installations that demand structural integrity, they are trusted by engineers and construction professionals for both industrial and commercial projects.

Fast Setting and Application Flexibility

With an initial setting time of just 3045 minutes, Shrinkkomp allows quick progress on-site, minimizing downtime. Their ease of mixing and application make them versatile for base plate grouting, machine foundations, and structural repairs.

Quality Assurance and Compliance

Manufactured with carefully controlled levels of SO3 ( 3%) and MgO ( 5%), Calderys Shrinkkomp guarantees long-term stability and minimizes cracking or shrinkage. Distributed throughout India, quality and compliance are assured at every stage.

FAQs of Calderys Shrinkkomp - 20, 30, 40:

Q: How should Calderys Shrinkkomp 20/30/40 be used on site?

A: To use Calderys Shrinkkomp, simply mix the powder with clean water according to the manufacturers instructions until a homogenous consistency is achieved. Apply promptly within the 3045 minute initial setting window for optimal results and ensure proper curing for maximum strength.Q: What are the main benefits of using Calderys Shrinkkomp grouts?

A: The primary benefits include high compressive ( 60 MPa) and bending strengths ( 8 MPa), rapid setting time, and reliable performance due to strict quality control of chemical composition. These properties ensure safety, longevity, and efficiency in demanding structural applications.Q: When is it advisable to use Shrinkkomp 20, 30, or 40?

A: Use Shrinkkomp grouts when high early and final strengths are required, such as in machinery base plate grouting, structural repairs, and precision installations where shrinking or cracking must be prevented.Q: Where can I buy Calderys Shrinkkomp products in India?

A: Calderys Shrinkkomp is available through authorized distributors, suppliers, and service providers across India. You can contact Calderys directly or partner businesses for the nearest supply point or for export inquiries.Q: What is the mixing and application process for Shrinkkomp?

A: The process involves gradually adding the grout to water while stirring continuously until a lump-free mixture is obtained. Immediately place the grout in the prepared area, ensuring it is properly compacted and free from voids.Q: How does the products composition improve its performance?

A: With low SO3 ( 3%) and MgO ( 5%) content, Calderys Shrinkkomp minimizes risks of undesirable expansion, cracking, or long-term deterioration, thereby enhancing the durability and service life of the installed structure.Q: What is the weight and packaging size of Shrinkkomp products?

A: Calderys Shrinkkomp is supplied in 50 kg bags, making it convenient for transport and handling on site, suitable for both small-scale and large-scale construction requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

S.K GUPTA PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry