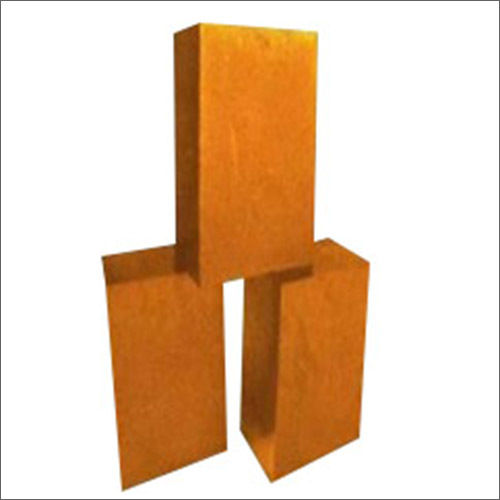

ACID RESISTANT BRICKS

ACID RESISTANT BRICKS Specification

- Usage & Applications

- Used for acid proof lining, industrial floorings, chemical plants, pharmaceutical plants, food & beverage processing units and sewage treatment plants.

- Hardness (%)

- >7 Mohs

- Application

- Chemical industry, battery rooms, laboratories, flooring, lining of tanks, ducts, and chambers exposed to acids and chemicals

- Chemical Composition

- Silica, Alumina, low iron content

- Water Absorption

- <0.5% (ASTM standard)

- Melting Point

- >1700C

- Purity(%)

- >97%

- Density

- 2.35 Gram per cubic centimeter(g/cm3)

- Form

- Solid Brick

- Surface Finish

- Smooth, fine finish

- Product Type

- Acid Resistant Brick

- Types of Refractories

- Acid Resistant Refractory Brick

- Shape

- Rectangular, also available in customized shapes

- Porosity

- Low (6-10%)

- Dimensional Stability

- Excellent, does not deform up to specified temperatures

- Strength

- Compressive strength >700 kg/cm

- Specific Gravity

- ~2.35-2.45

- Thermal Conductivity

- Very low, ~0.8-1.0 W/mK at 100C

- Color

- Red, Brown, Terracotta

- IS Standard

- IS 4860:1968

- Flexural Strength

- >100 kg/cm²

- Shelf Life

- Unlimited under proper storage

- Standard Size

- 230 x 115 x 38/75 mm (as per IS 4860:1968), other sizes on request

- Abrasion Resistance

- High, suitable for industrial traffic

- Acid Resistance

- >99% against most inorganic acids except hydrofluoric acid

- Fire Resistance

- Excellent

- Packaging Type

- Wooden pallet with shrink wrap or as per customer requirement

About ACID RESISTANT BRICKS

Customers can purchase theseAcid Resistant Fire Bricks from us in different sizes and surface finishes. They are widely demanded in food processing, pharmaceutical, chemical, power generation and other industries. In order to save energy, they provide low thermal conductivity for high efficiency. The provided bricks are used to manufacture fireboxes, fireplaces, kilns & lining furnaces. A team of adroit professionals manufactures these Acid Resistant Fire Bricks with the use of premium quality raw materials and sophisticated machine.

We manufacture Acid Resistant Bricks, which are brown/Grey in colour for IS-4860 and white in colour for IS-4457 standard. The colour of the bricks does not have impact on the performance of the bricks. These bricks have good density and low water absorption and low porosity. Very high cold crushing strength, High resistance to strong acids (except hydrofluoric acid) and partial resistance to alkalies are the important technical parameters of these bricks. These bricks are used in various industrial applications like Chemical Storage Tanks, Absorption towers, Process Tanks, Flooring, vessels, Chimney lining etc. in Chemical, Dyes and Intermediates, Alkalies, Fertilizers, Petrochemicals, Paper, Power and Steel Plants, and many more.

|

Product |

Chemical |

Physical |

|||||||||

|

SiO2 |

Al2O3 |

Fe2O3% |

TiO2 |

CaO+MgO % |

Na2O+K2O % |

Water Absorbtion % |

C.C.S Kg/Cm2 |

Flexural Strength Kg/Cm2 |

Acid Resistance % Loss In Wt. |

||

|

SKG-AR 230 X 115 X 75mm |

68.2 |

24 |

1.8 |

2.1 |

0.5 |

3.4 |

3 |

730 |

125 |

0.80 |

|

|

SKG-AR 230 X 115 X 38mm |

68.2 |

24 |

1.8 |

2.1 |

0.5 |

3.4 |

3 |

730 |

125 |

0.75 |

|

Unmatched Acid and Chemical Resistance

Our Acid Resistant Bricks are engineered to withstand the harshest chemical environments, with over 99% resistance against most inorganic acids. Their low porosity and smooth surface finish further enhance chemical durability, making them a reliable choice for industries handling aggressive substances.

Versatile Applications Across Industries

Designed for a range of demanding uses, these bricks are perfect for acid-proof linings, industrial floors, chemical plant storage, battery rooms, and laboratory counters. Their excellent abrasion and fire resistance enable them to handle heavy machinery, frequent traffic, and high-temperature exposure without compromising integrity.

Superior Strength and Longevity

Crafted from high-purity silica and alumina, with compressive strength exceeding 700 kg/cm, the bricks retain their form and function even in extreme conditions. Properly installed and maintained, they offer an unlimited shelf life and guarantee long-term value in your operations.

FAQs of ACID RESISTANT BRICKS:

Q: How are acid resistant bricks installed in industrial environments?

A: Acid resistant bricks are typically installed using acid-resistant mortars over prepared surfaces. The installation process involves cleaning the substrate, applying a suitable primer, and then laying the bricks in the desired pattern to ensure tight joints and maximum chemical resistance.Q: What benefits do acid resistant bricks offer over conventional bricks?

A: Unlike conventional bricks, these specialized bricks offer superior resistance to most inorganic acids, high compressive and flexural strength, low water absorption, and excellent abrasion resistance. This ensures durability, longer service life, and reduced maintenance costs in harsh industrial settings.Q: When should I choose acid resistant bricks for my project?

A: You should opt for acid resistant bricks whenever your application involves exposure to corrosive chemicals, acids, or frequent industrial wearsuch as in chemical plants, laboratories, battery rooms, pharmaceutical and food processing units, or sewage treatment plants.Q: Where can acid resistant bricks be used effectively?

A: These bricks are commonly applied for acid proof lining in tanks, ducts, chambers, industrial flooring, as well as surfaces in chemical and pharmaceutical plants, laboratories, battery rooms, and food and beverage processing units.Q: What is the standard size of these bricks and can they be customized?

A: The standard size is 230 x 115 x 38/75 mm, as per IS 4860:1968. However, we can also supply customized sizes and shapes upon request to fit specific project requirements.Q: How does the bricks chemical composition contribute to its performance?

A: The bricks are made from high-purity silica and alumina with low iron content, resulting in high resistance to acid attack and thermal shock. The low porosity (6-10%) further boosts their protective qualities and lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Minerals & Refractories Category

Magnesite Bricks

Shape : Other, Rectangular (as shown in image)

Color : Yellowishbrown

Application : Lining of furnaces kilns converters and other hightemperature industrial equipment

Types of Refractories : Basic Refractory

Product Type : Other, Refractory brick

FIRE CLAY

Minimum Order Quantity : 1000 Kilograms

Shape : Powder

Color : Brown

Application : Industrial

Types of Refractories : Basic Refractory

Product Type : Mineral Refractories

ACCPLAST 80

Minimum Order Quantity : 1000 Kilograms

Shape : Powder

Color : Black

Application : Industrial

Types of Refractories : Basic Refractory

Product Type : Mineral Refractories

MAGNESIA CARBON

Minimum Order Quantity : 1000 Pieces

Shape : Brick

Color : Black

Application : Industrial

Product Type : Mineral Refractories

|

S.K GUPTA PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry